In 2005 the FiBO Interferometer had just been introduced onto the market. One of its first customers was a US national lab that had spent significant funds updating its campus network to deliver multiple Gb to individual work stations. This was a state-of-the-art network. When the installation was finished, they flipped the switch. It didn’t work. They didn’t understand why.

Someone on their network team was learning about endface geometry, what it was and why it mattered. They began testing the installed patchcords and found that their state-of-the-art, high speed network was not working properly due to poor quality patchcords and cabling.

Using an interferometer re-tested and ultimately replaced a significant portion of these network components. How much did it cost to re-test and re-install large portions of the network? The exact cost we will never know, but the cost must have been significant.

Has this situation ever happened to you? Did you install something without ensuring sufficient quality of the components? Did you even know what “sufficient” quality was?

This situation often happens to groups that generally work with copper communication systems but need to integrate fiber. Lack of awareness and knowledge can lead to insufficient patchcord quality control (QC). This in turn can lead to excessive troubleshooting and ultimately unavoidable re-work.

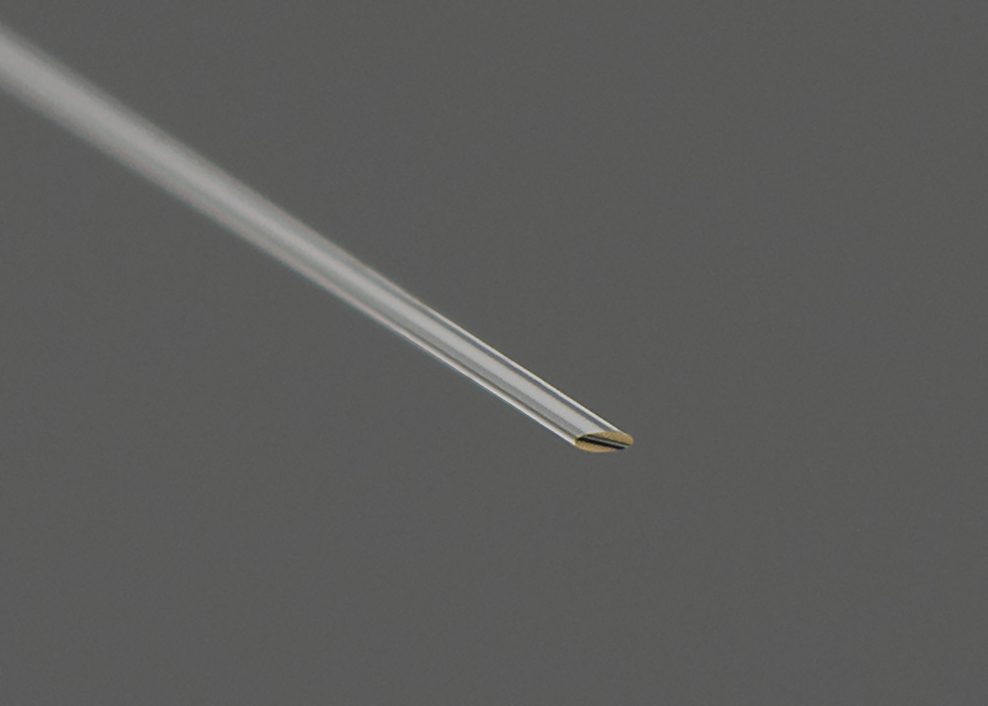

Fiber optic patchcords come in a variety of styles: simplex jumpers, duplex jumpers, fanouts, pigtails, crossovers, etc. The terminations for these patchcords are typically done by fiber cabling manufacturers or by in-house fiber termination production facilities.

A number of QC testing procedures are generally performed on terminations at the manufacturing level. They include but are not limited to the following:

- Post polish visual inspection: Confirm that the polish was completed correctly and Look for scratches, defects, pits, cleanliness, etc.

- Insertion Loss: Determine the amount of light lost during coupling

- Link Loss: Show the overall signal loss

- Back reflection: Show amount of light reflected back from the interface

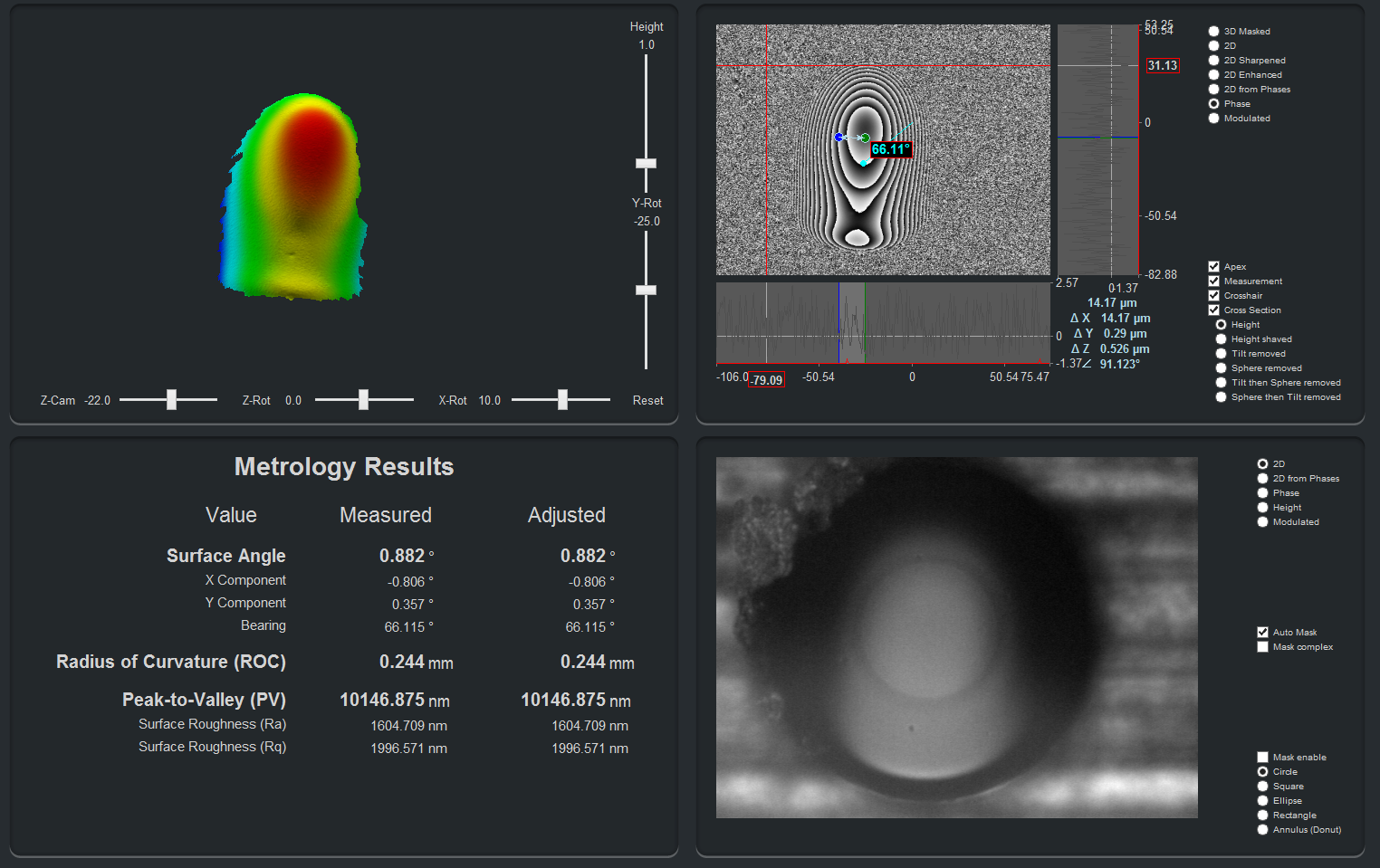

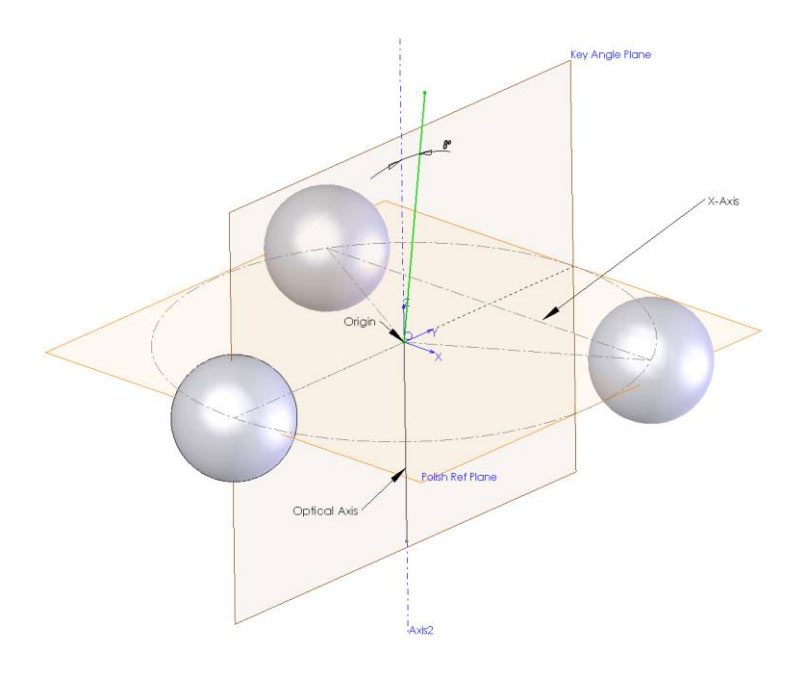

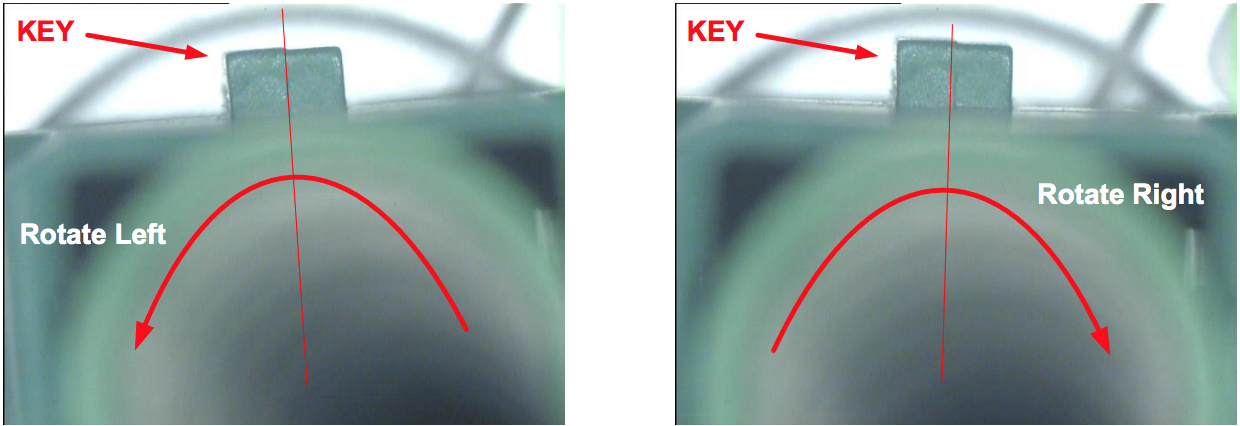

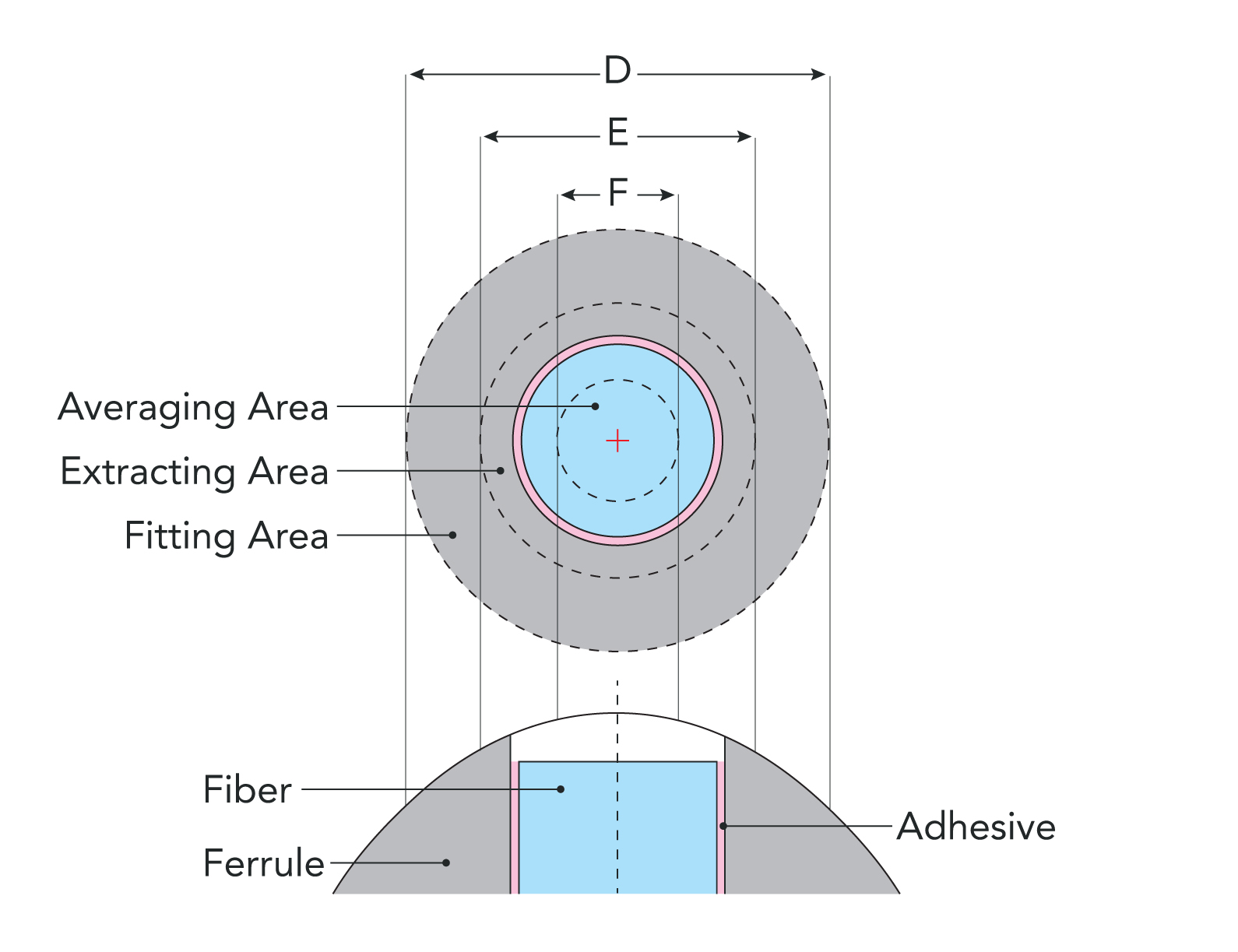

- Endface geometry: Physical geometry of the connector endface

The type and frequency of testing depends upon specific customer requiresments. Each type of test provides different information regarding the patchcord’s funcitionality. The desired performance of the final system should drive kinds of QC tests that are required.

However, more testing means a higher patchcord cost. But what are the cost associated with troubleshooting and re-work? This is obviously a very important balance.

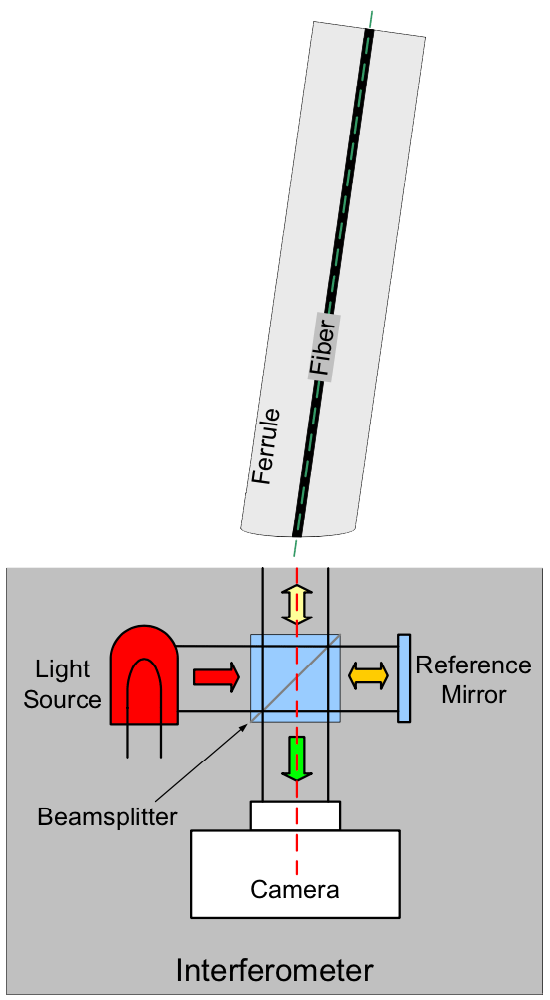

Interferometric endface geometry inspection is an important part of the patchcord manufacturing process, however it may not be done at the manufacturer level unless specifically required by the customer. In such a scenario, where patchcord manufacturing is subcontracted, having an in-house interferometer for incoming QC can save significant costs in troubleshooting of installed patchcords.