We all use a world-wide integrated communication network every day. Each phone, computer, TV, satellite and radio is connected by a vast system that can be overwhelming to even think about. Fiber optics allow for the transmission of huge amount of data being every second. An excellent description of fiber optic communications can be found on Wikipedia.

The basic components of a communication system are: a transmitter, channel, noise and receiver. What is overlooked in this picture? The connections. The transmitter couples to the channel through a connection. The channel will likely have many, connections before it reaches the receiver. Each one of these connections will introduce some level of noise as well as degradation of the original signal. Minimizing this noise and degradation is a significate aspect of the overall communication system design and execution.

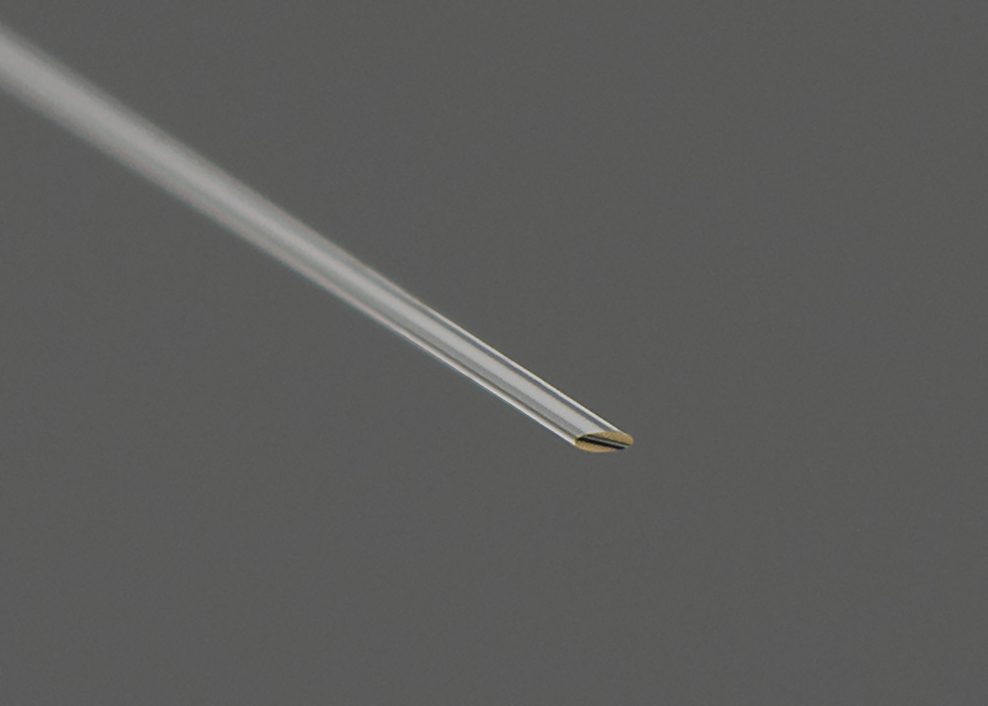

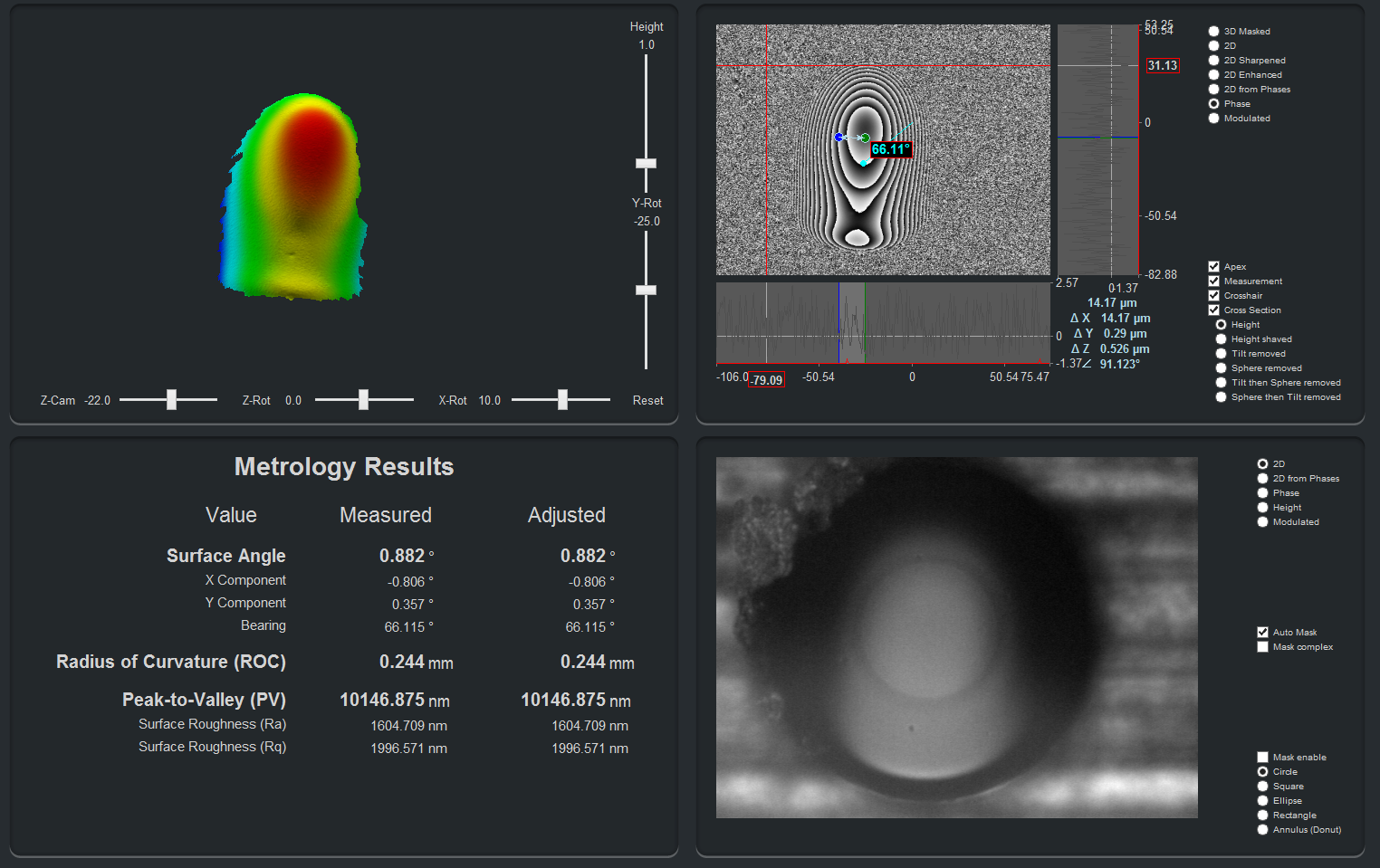

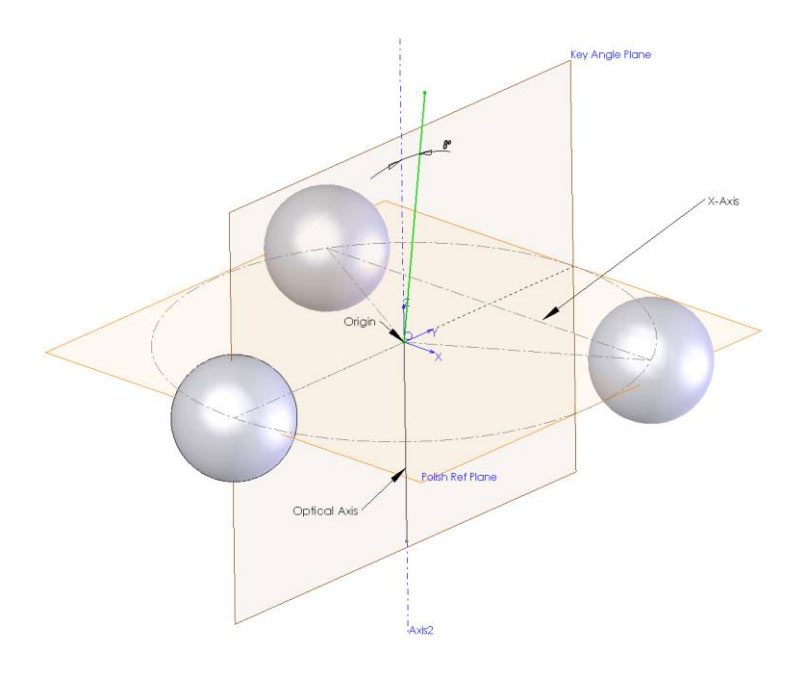

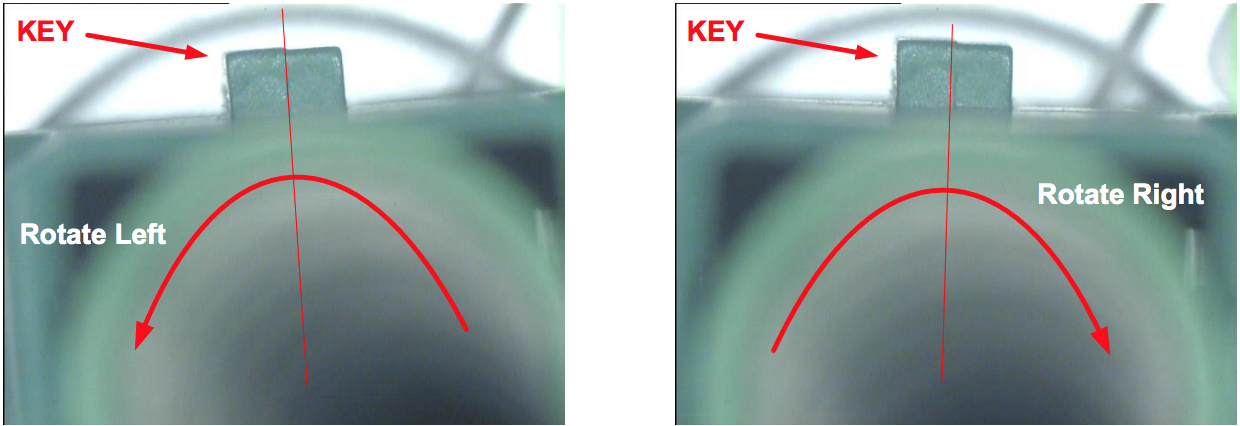

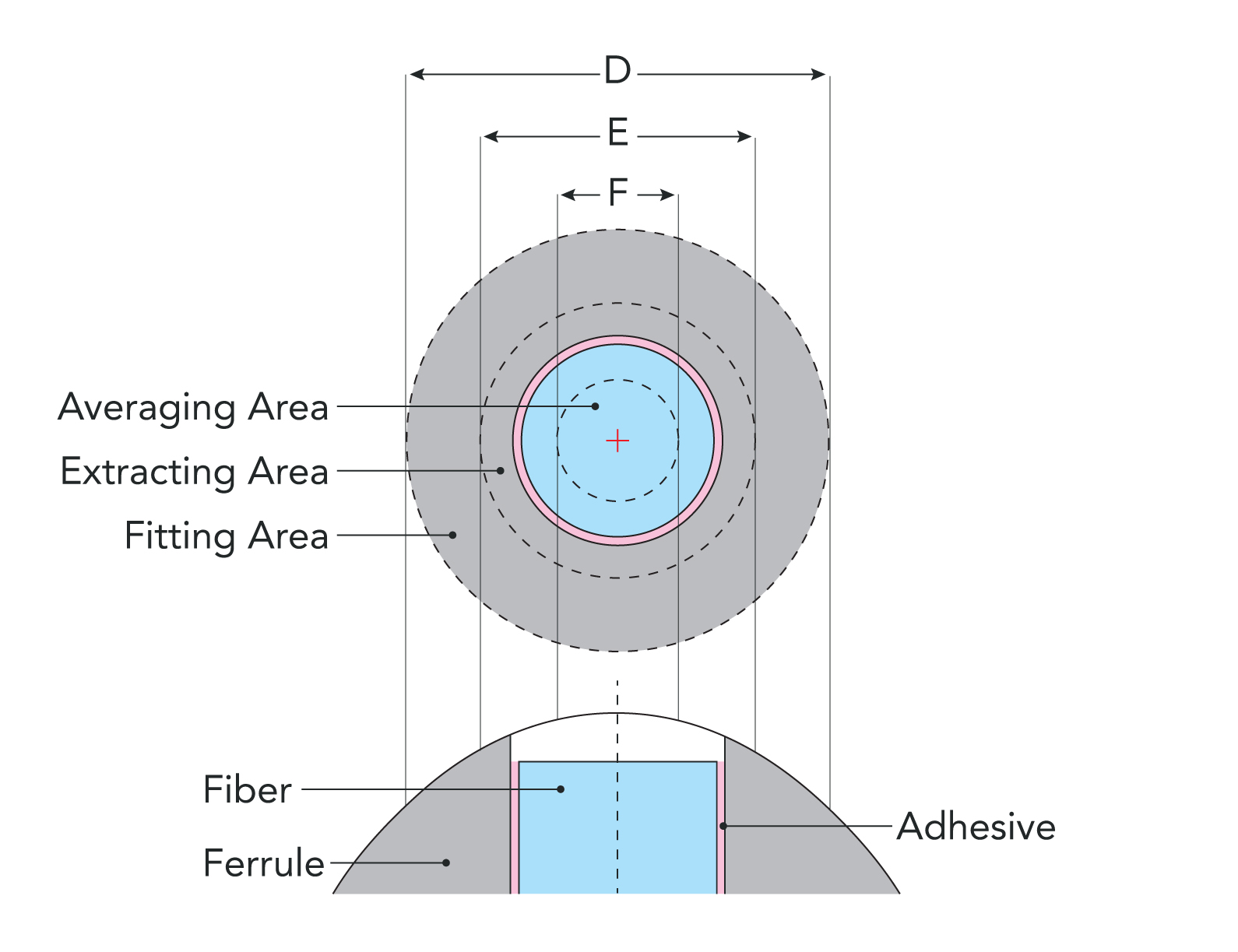

In a fiber optic connection, two optical fibers are mated together to ensure the optical signal in one fiber is transmitted into the other. These fibers are roughly the size of a human hair, and must be touching end-to-end and perfectly aligned. The technical details of light propagation through optical fiber can be found in any Optical Communications text book, these details then gives rise to the requirements for proper mating between two fibers. Suffice to say that modern fiber optic connectors are designed to do exactly that. The connector mating process is heavily dependent on the actual physical shape of the tip of the fiber, or commonly known as fiber endface, meeting certain criteria. Understanding these criteria; what they mean and how they are applied in different situations is essential to minimizing noise and signal degradation through a fiber optic connection.

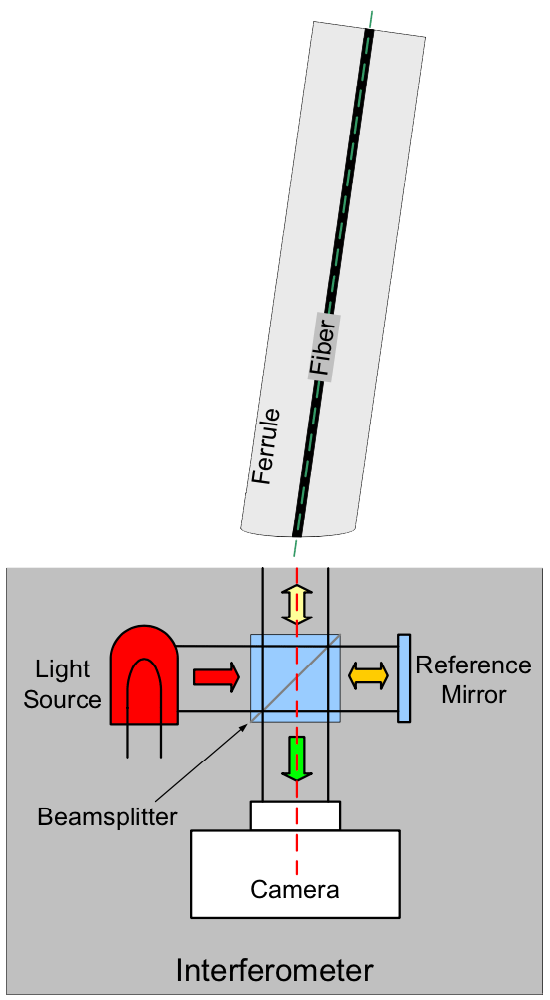

This Fiber Endface Blog, presented by FiBO Interferometers, will explore issues relevant to the overall endface health as well as the manufacturing processes that create and shape the physical tip of fiber optics. Interferometric measurement of endface geometry will be the primary focus, however, content covering cleaving, polishing and cleaning will also be presented in collaboration with industry leaders in their prospective fields.

Initial topics will include a basic exploration of applications that utilize interferometric endface geometry inspection. Also, answering the question; “What is endface geometry and why do I need to measure it?” will also discussed.

Promet Optics is a Fiber Optics Company providing precision optomechanical design and production for applications. Don’t hesitate to contact us online, by phone or in person to learn more!